Technical processes provided by Tecniplast

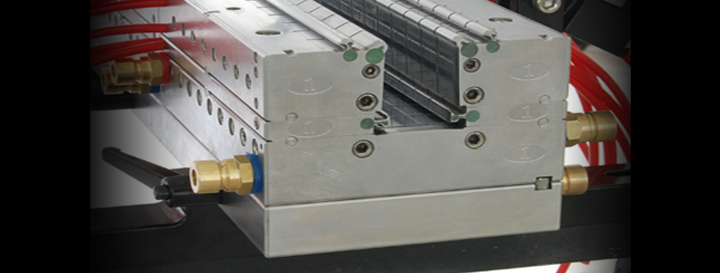

Extrusion molding

Manufacturing process by which a material is mechanically compressed and pushed to go through a mold in the shape of the part to be obtained. Most commonly used to produce long shapes (tube, pipe, profile) that will be measured and cut afterwards.

Embossing

Technique aiming to create raised shapes in any deformable material. With PVC, cold or hot embossing is used to create shapes.

Machining

If necessary, PVC parts could undergo a secondary machining operation in order to adapt to other products.

Assembling

If necessary, PVC parts could undergo assemblies to each other or to other parts, in a secondary operation, in order to obtain a finished product.

Painting

If necessary, PVC parts could be painted in a secondary operation.

Custom design

All processes offered, give free rein to your imagination.